About us

CLT Rezult is the first and only manufacturer and supplier of multi-layer cross-laminated timber (CLT) panels in Ukraine.

We are introducing innovative CLT panel construction in our country. We provide consultations, educate and accompany you, from the creation of an architectural solution to the construction of a house.

What are CLT panels?

CLT (Cross-Laminated Timber) is a solid wooden panel, which consists of 3, 5, 7 or 9 layers of softwood glued together in a crosswise manner.

CLT is a unique building material that confidently competes with steel and concrete. It is environmentally friendly and energy-efficient, with high strength and rigidity.

This is the next generation in the design and construction of single-storey and multi-storey buildings made from natural wood. Construction technology using CLT panels is a global trend.

Since 2023, as Ukraine undergoes reconstruction, the Ukrainian CLT market has been actively expanding. There is a growing demand for sustainable, eco-friendly, and energy-efficient construction.

Own production

Rezult is one of the largest woodworking holdings in Eastern Europe, which includes full cycle production.

The capacity of our complex is 1.2 million m3 of wood per year. The main products of the Rezult brand: lumber, MDF, glulam, laminate, parquet, furniture panels, doors and others.

Also, one of the directions of our factory is the production of CLT panels. The annual capacity of the CLT panel production line is more than 91 thousand m3..

A guarantee of stability – from partnerships to product quality and timely deliveries.

The factory produces ready-made parts, with slots for windows and strobes for communications – the house can be assembled in 1 day. Quick assembly, with minimal mess, and on-site construction saves time and lowers overall costs.

Panel sizes – up to 18 m x 3.5 m. Number of layers – 3, 5, 7, 9. Thickness – from 60 to 360 mm. PUR - one-component polyurethane glue without formaldehyde. Coniferous wood (pine, fir, larch).

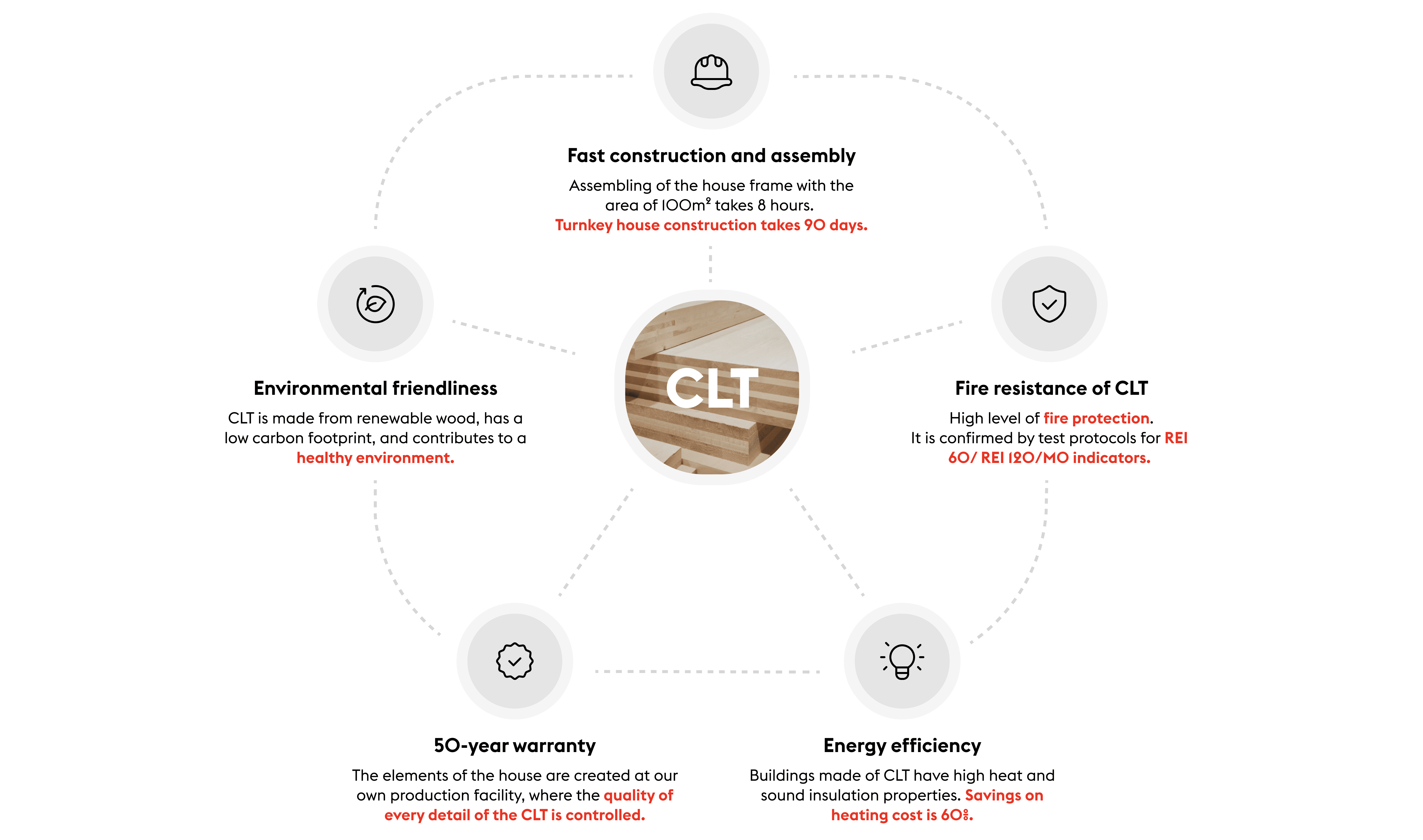

Benefits of CLT

CLT. Revolutionary construction technologies

СLT винятково добре справляється з пожежами, завдяки повільному обвуглюванню та самоізолюючим властивостям деревини, що забезпечує ефективний протипожежний захист. Вогнестійкість – це здатність матеріалу продовжувати забезпечують структурну міцність та стійкість до тепла та диму, під час пожежі. Рейтинг вогнестійкості відноситься до часу, який компонент будівлі може витримати, під час пожежі та порушення її цілісності.